HENKER Ltd.

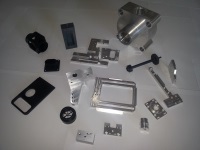

Part manufacturing to the highest standards

Custom and serial production, CNC milling and turning

About us

Our company was established in 1994. The main profile was moldmaking, our aim was to provide reliable quality while maintaining favorable prices. These two principles have characterized our operations over the years, wich we can continue to rely on through the 40 years of professional experience and continuous technical developments.

In 1997 we became a limited partnership company, but we managed to keep the family business type, which is an important basis for our trustworthiness.

In 2001, besides moldmaking, we began to deal with parts manufacturing, which later became the company's main business.

In 2003, we bought our first CNC machining centre, followed by the purchase of several new and used machines.

In 2008, in order to meet the increased space requirements, our company purchased a 600 m2 of new site with the use of tender resources.

Since 2015, we have ISO 9001 and ISO 14001 certifications.

In 2016 we became a limited company, the ownership structure remained unchanged. By increasing our staff and purchasing a CNC coordinate measuring machine, we extend our capacity and raised our quality control to a higher level.

In 2017, we bought our first industrial robot for the production of a new series as our first automation project.

Currently we are manufacturing metal, plastic and precious metal parts in small and medium series, for domestic companies with international markets. Surface treatments are performed through partner organizations with ISO qualification.

Our main clients:

77 Elektronika Ltd. - medical instruments and aids

Festo-AM Ltd. - pneumatic systems

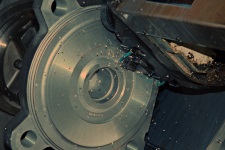

Machine park

CNC mills:

Akira-Seiki Performa V2.5 - vertical machining centre

Akira-Seiki Performa PC700 - high-speed drilling and milling centre

Akira-Seiki RMV700 - four-axis twin-pallet vertical machining centre

Bridgeport VMC2000 - four-axis vertical machining centre

Brother TC-32A - four-axis twin-pallet vertical machining centre

Famup MCX1000 - twin-pallet vertical machining centre

Kondia B640 - vertical machining centre

YCM FV56A - twin-pallet vertical machining centre

CNC lathes:

Citizen Cincom L25 + IEMCA CNC Boss 542 - twin-spindle sliding head lathe with automatic bar loader

Gildemeister CT40 - turret lathe

Gildemeister CTX500 - turret lathe with driven tools

Quicktech T8 + Comau Robot Racer7 1.4 - twin-spindle turret lathe with driven tools and robot part changer

Topper NCT TNL-100ADT - turret lathe with driven tools

Other machines:

Conventional cutting machines

Sawing machines

Abrader

Robot technology

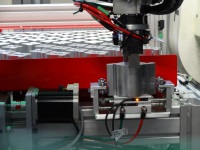

Our first industrial robot was purchased in 2017. The Comau type machine is installed to a twin-spindle CNC turret lathe, delivering 24-hour continuous production. The design and implementation of the equipment was carried out by Fipa Magyarország Ltd.

Measurement techniques

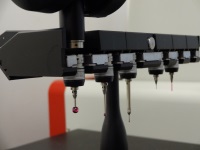

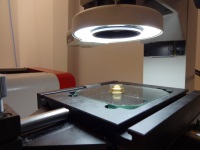

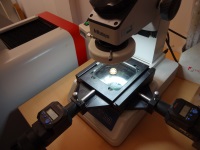

The full-scale high-precision inspection of our parts is carried out with a five-axis CNC coordinate measuring machine and an optical measuring microscope placed in an air-conditioned measuring room. Upon request we prepare the inspecting documentation of the manufactured products.

Contact

Office: 2040 Budaörs, Kolozsvári u. 35.

Tel/Fax: +36 23 431 296

Site: 2316 Tököl, Ráckevei út 10.

Tax number: 25751624-2-13

E-mail: info@henker.hu